1,100 years of precious

metal expertise

At The Royal Mint we know how to handle valuable materials at scale. Our Reformation Metals division now builds on that legacy, with a world-leading capability to cleanly recover critical metals from e-waste.

Drawing on 1,100 years of our expertise, we’re investing in a breakthrough new process to safely retrieve and recycle precious metals from PCBs.Sean MillardChief Growth Officer, The Royal Mint

The Story of Reformation Metals

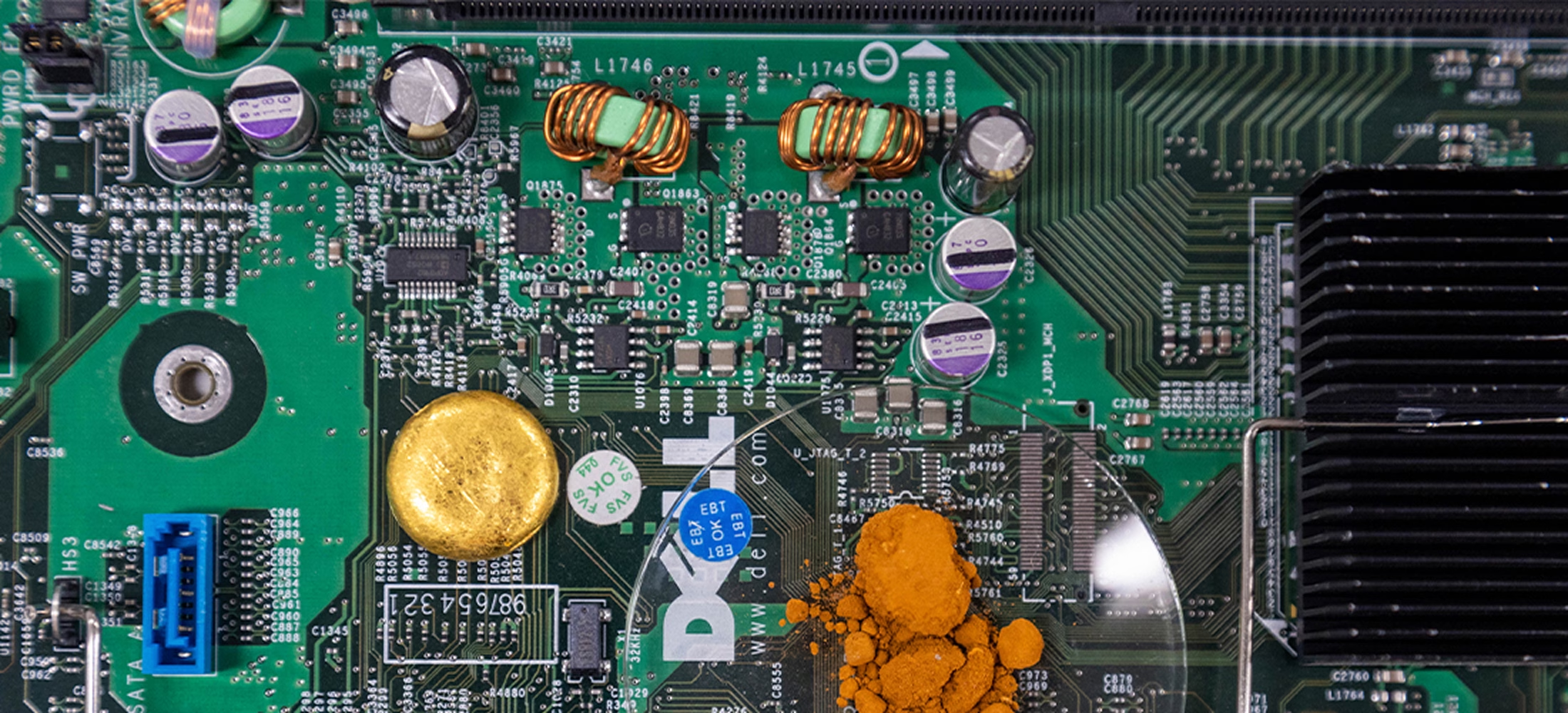

In 2024, The Royal Mint partnered with Canadian clean tech company Excir to implement their historic, world-first process for the chemical reclamation of precious metals. From this, Reformation Metals was born.

The partnership with Excir deepened further in 2025, when The Royal Mint made a significant investment in the company.

Together, as Reformation Metals, we are taking the steps to create a circular economy for precious metals, tackling the issue of PCB recycling head-on, and pushing for a sustainable future.

Together, we are transforming waste into valuable resources and driving a more sustainable future.Aaron LoganChief Executive Officer, Excir

Careers

Be part of a storied legacy. Help build a sustainable future.

With over 1,100+ years of experience, joining the Reformation Metals team at The Royal Mint is your opportunity to be part of that history. As we look ahead, join our team to help write the next chapter in our story.

1/10,000TH

The carbon footprint of newly mined gold.

Our low-carbon, clean-tech process brings precious metals back into circulation, reducing the reliance on mining. Recovered PCB gold has just 1/10,000th the carbon footprint of newly mined gold.

Process

The world’s most advanced facility for recovering precious metals from PCBs.

Working with partners, our precise mechanical separation, combined with patented clean-tech chemistry, enables the complete recovery of materials from printed circuit boards (PCBs).

Resources

How OEMs Can Lead the Circular Economy Revolution

OEMs can drive the circular economy through design, recycling and ESG leadership. Discover how sustainability boosts brand trust and profitability.

Closing the Loop: Turning E-Waste into a Strategic Resource for the UK

Discover how recycled gold can cut emissions, boost the circular economy, and secure strategic resources.