Resources / Insights

Closing the Loop: Turning E-Waste into a Strategic Resource for the UK

7% of the world’s gold supply has been lost, trapped in unrecycled electronic waste. The UK can lead the way on turning this into an economic opportunity.

Demand for gold is surging. Market volatility from tariffs and global instability has seen investors put money into gold as a reliable store of value.

Gold prices have surged well past US$4,000 per ounce in 2025, with global demand rising to

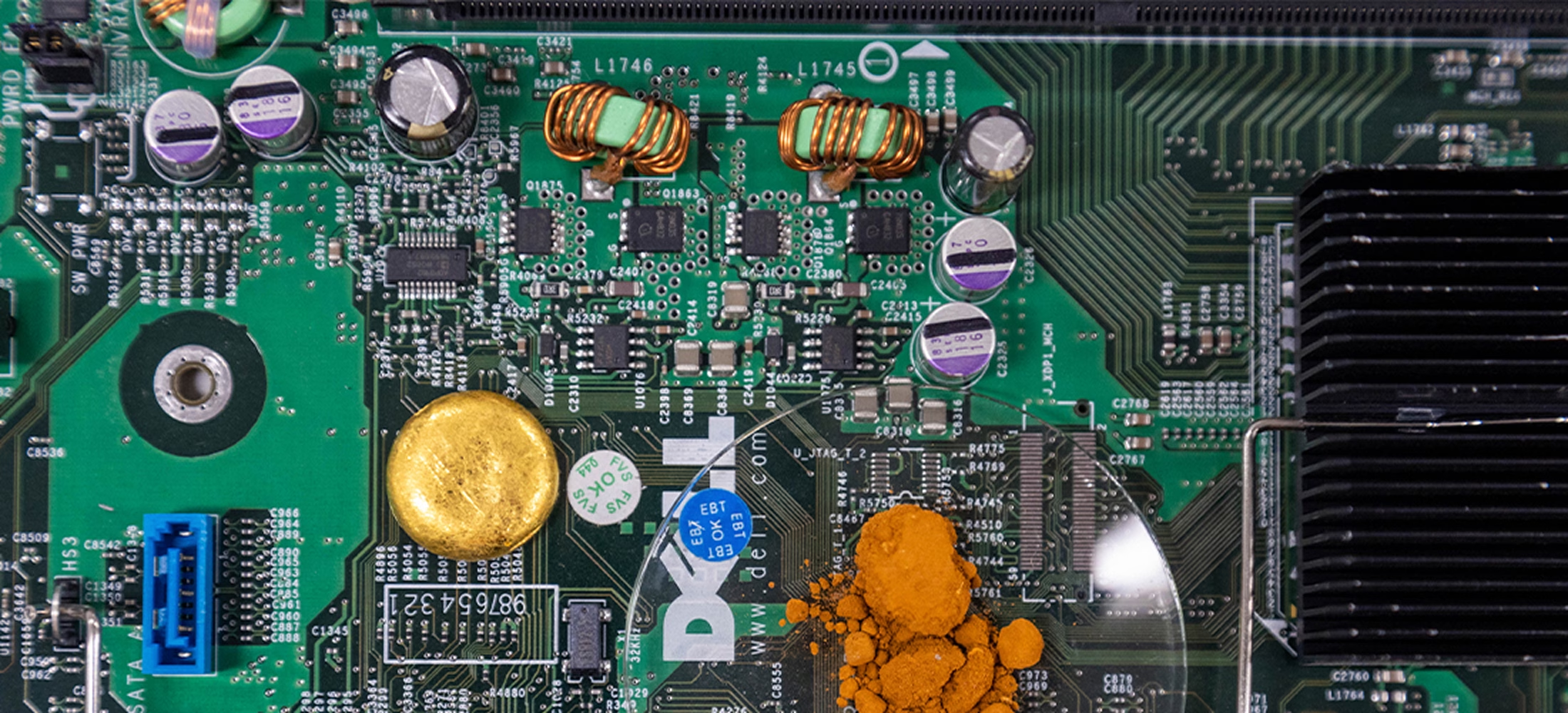

Gold is a fundamental precious metal, not only for investment and ornamentation, but also for its practical applications. Gold’s natural conductivity, resistance to corrosion, and malleability make it a highly practical metal for several key industries and tech sectors like electronics, aerospace and medical science. Much of this practical gold, used in printed circuit boards (PCBs), ends up as e-waste.

How much gold is in e-waste?

E-waste is the fastest growing waste stream in the world This is expected to rise to 81 million tonnes by 2030, and 120 million tonnes by 2050. The Global E-Waste Monitor estimates that only about 17% of this e-waste is being managed or recycled properly. Herein lies a huge opportunity.

E-waste contains as many as 69 different chemical elements per the UN report, including abundant precious metals. The Royal Mint estimates that, on average, one tonne of circuit boards produces 165g of gold.

Potentially hundreds of tonnes of gold are lost each year, trapped in unrecycled PCBs. The material value of e-waste is estimated to be at least US$62.5 billion, more than the annual GDP of most of the world’s countries.

Is gold running out?

If large quantities of gold are lost to each year, why is this a problem? Beyond the obvious issue with waste of any kind, this is an issue of resource management.

Gold has always been scarce – The World Gold Council estimates that only 216,265 tonnes have ever been mined. Roughly 3,000 tonnes are mined each year, with the rate slowing year-on-year from an all-time high in 2018, as previous sources are depleted and fewer new sources are found. There aren’t many unexplored regions of the world left in which to discover new gold deposits.

There are also concerns that humanity may have reached ‘peak gold’, the point at which there is less gold left in the ground than has already been mined. This is particularly true of a country like the UK, where natural gold deposits have been depleted, and which cannot compete with large gold-producing nations like China, Russia, the US and Canada. But gold is unlike other finite resources, for example oil. Gold never ‘runs out’, it can be recycled.

The opportunity for the UK to lead on recycled gold is an unfortunate consequence of the UK’s massive generation of gold-containing e-waste it generates each year.

As part of a move towards a more circular economy, we should look not only to minimising the waste we generate, but also how we can productively return our waste to use where possible. This is particularly key with e-waste, where according to the UN, new electronic items are being produced at a rate five times higher than the rate at which they can be recycled.

E-waste gold is valuable, recoverable, and fully recyclable, so it is an important part of a transition towards greater sustainability practices.

What are the benefits of ?

As the gold used in PCBs has already been refined for use, it is of a high quality by default. Less work is required to create high purity gold once it has been obtained from e-waste. This solves a huge logistical challenge in obtaining gold and precious metals – they can be recovered from PCBs with the right skills, expertise, equipment and technology, without the need to refine ore.

Besides logistics, current methods of gold extraction are highly carbon intensive and environmentally destructive. Mining gold is also extremely capital intensive. Whether in underground mines or in surface mining, it requires large and expensive machinery as well as skilled, expert workers. An ounce of gold can cost US$500 to US$1,000 to produce.

A new and increasingly widespread practice is urban mining – extracting precious metals from waste, particularly e-waste like mobile phones. The World Economic Forum (WEF) estimates that there is 100 times more gold in a tonne of mobile phones than in a tonne of gold ore. WEF also estimates that urban mining is much less negatively environmentally impactful.

It is also a benefit to the circular economy by creating financial incentive. WEF cites a study from Switzerland where participants were willing to sell their old phone for less than US$5. This phone contains metals with a market value under US$2, but the external costs of extraction the cost of those same materials is around US$18.

Recycled gold from PCBs has been shown to have . Precise mechanical separation removes gold-containing elements from PCBs. We then use a patented, reusable chemical solutions under laboratory conditions to separate the gold into powder, which can then be reconstituted to an ingot of 99.99% purity. The Royal Mint then uses this reformation gold for our 886 jewellery brand.

Gold and e-waste – tackling two problems at once

At present the world is throwing losing valuable precious metals on an industrial scale in the form of e-waste. According to the UN E-Waste Monitor, the UK alone is generating roughly 1.65 million tonnes of e-waste every year, of which only 30% is formally recycled. The rest of our e-waste is not formally recycled, but incinerated or exported with materials lost, when the UK has ability to create the domestic capacity to handle it ourselves.

From these millions of tonnes of e-waste, we are losing tonnes of gold and millions (potentially billions) of pounds. It is hard to conceive of other circumstances where such waste would be tolerated, and yet it has become the norm. What is required is a complete shift in mentality. By seeing e-waste as something of value to the wider economy, we can transform the recycling journey of e-waste more broadly.

This is not only financially beneficial, but also more beneficial for the environment. Reformation Metals have started this conversation. That’s why we’ve invested in state of the art facilities and pioneering groundbreaking new cleantech to harness the full value from the UK’s e-waste.

By taking control of our e-waste, we can tackle two problems at once. Firstly, addressing the strategic need to conserve precious metals (specifically gold) in the UK. Secondly, tackling the problem of e-waste generally. By keeping e-waste in the UK, we can ensure that it is being recycled properly, with a clear chain of custody. It won’t be an overnight change, but by beginning a conversation with recyclers, manufacturers, government and the public, the UK can become a world-leader in a new gold recycling industry.